KGHM

BESTECH evaluated battery electric vehicles (BEVs) for the KGHM Victoria Mine project, focusing on prime mover and utility BEV equipment.

The project included a detailed cost-benefit analysis comparing BEVs with traditional diesel-powered equipment, considering development, capital, operating, maintenance, and handling costs.

SCOPE

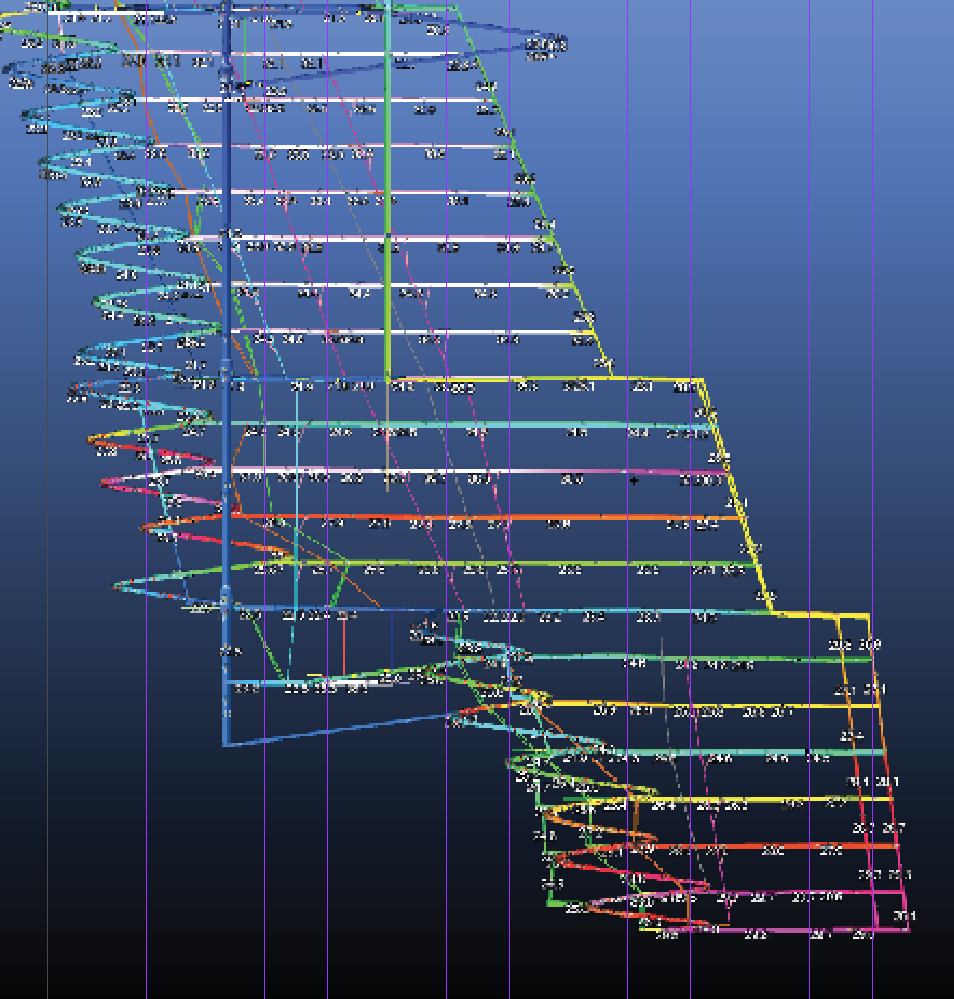

BESTECH’s analysis extended to reviewing the total cost of ownership and the comparison of performance and carbon emissions between BEVs and diesel vehicles, as well as determining the ideal locations for charging stations and the necessary training and maintenance for operating BEVs.

BESTECH also evaluated potential savings from reduced ventilation, cooling, and heating costs due to BEV implementation. The project included applying for funding through the IESO’s Industrial Energy Efficiency Program “Save On Energy” and conducting a Detailed Engineered Study (DES) to determine eligibility for grants and incentives related to Ontario’s critical mineral strategy.

OUTCOME

The comprehensive assessments and analyses provided by BESTECH highlighted the substantial benefits of transitioning to BEV technology at the KGHM Victoria Mine. This included significant reductions in greenhouse gas emissions and operational costs, alongside enhanced safety due to lower fire risks and electric shock hazards associated with BEVs. The findings facilitated strategic planning for BEV implementation, optimizing the mine’s construction and operational phases for efficiency and sustainability.